HEXAGON Production Software Portfolio to Feature at SIANE 2019

Connected Data Leads to full digital continuity for compliant and quality parts, every time

Visitors to the forthcoming Siane exhibition in France will see at first hand how the latest releases of EDGECAM, WORKPLAN and WORKXPLORE solutions from Hexagon’s Production Software portfolio, enable new products to be designed, visualised and produced quickly and cost effectively.

More than 10,000 visitors at the 15th Siane trade fair, between October 22 to 24 at the Toulouse Exhibition Centre.

Demonstrations on the Hexagon booth - Y18 in Hall 6 - will show how step-by-step how parts are evolved digitally before being launched into production, thanks to a set of automatic CAD/CAM and viewing software, connected to metrology tools. This demonstrates a real digital continuity with HEXAGON production software solutions.

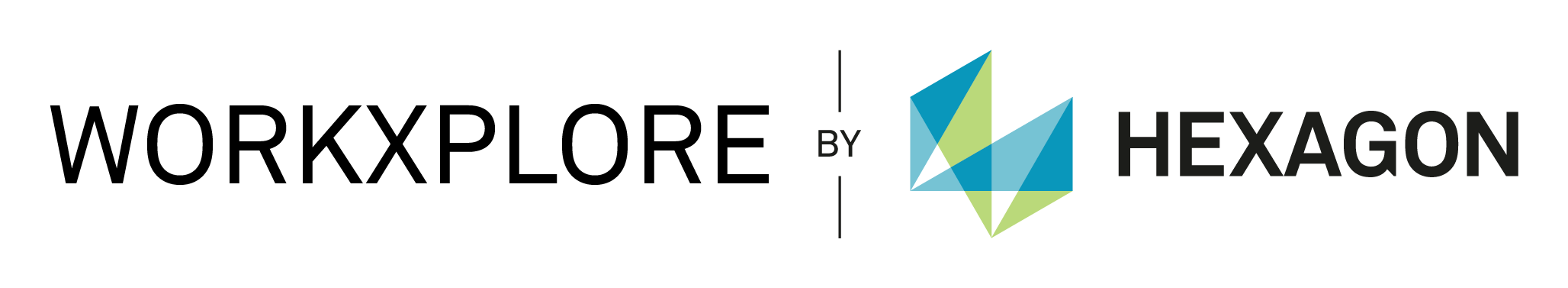

The EDGECAM mill-turn CAM solution, one of the links in the HEXAGON digital chain, meets the needs of the aeronautics, automotive and general mechanics sectors by integrating a high speed machining technique for turning and milling. The Waveform roughing strategy optimises the machine's agility, reducing cycle times, maintaining a constant cutting force and ensuring a longer tool engagement in the material, while improving tool life.

In the latest version, EDGECAM's ability to program barrel mills using new 5-axis algorithms significantly reduces cutting and machining times, while obtaining optimal surface finish results.

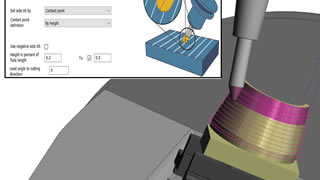

With EDGECAM Inspect, the developers have met many customer expectations by increasing component inspection capabilities in the turning and milling environments. The interface has been globally updated to adopt the ribbon work process, improving interactivity. The "Probing Options" menu has been divided into two dialog boxes, allowing users to focus separately on Generation and Inspection preferences.

The WORKPLAN project management solution is repositioning itself to reflect its new range of functionalities. In its new version, data from the workshop will be automatically consolidated allowing for real time viewing, in a single application.

These new functions are said to improve production management by integrating machine events, monitoring, computer-aided maintenance management (CMMS), CAM supervision, workflow and part traceability.

WORKPLAN is Hexagon’s first production management solution to combine an ERP integrated management software package with MES industrial process management functions in a single database.

WORKXPLORE visualises and analyses 3D models directly from CAD files without using the original CAD software. The easy-to-use 3D collaborative software provides an effective tool to explore all types of 2D/3D data, while also managing Product Manufacturing Information (PMI).

Antonio PARISSE, Hexagon Production Software’s General Manager France, explains: "Our customers are increasingly being asked to recover the PMI generated by the main CAD systems. PMIs make it possible to delete 2D plans, and improve the reliability and security of the transmitted information. Its exceptional level of recovery allows you to go to ‘views’ - for example defined in CATIA."

EDGECAM, WORKPLAN, WORKXPLORE, Siane, from 22 to 24 October, HEXAGON MANUFACTURING INTELLIGENCE Hall 6, booth Y18.